Plastic waste

Plastic waste comes in all shapes and forms, from films and bottles to trays and crates or production waste such as rolls and pipes. Each type requires a different approach. BOA offers complete solutions for processing plastic waste, both from household and industrial production processes.

Plastic waste from household or commercial waste

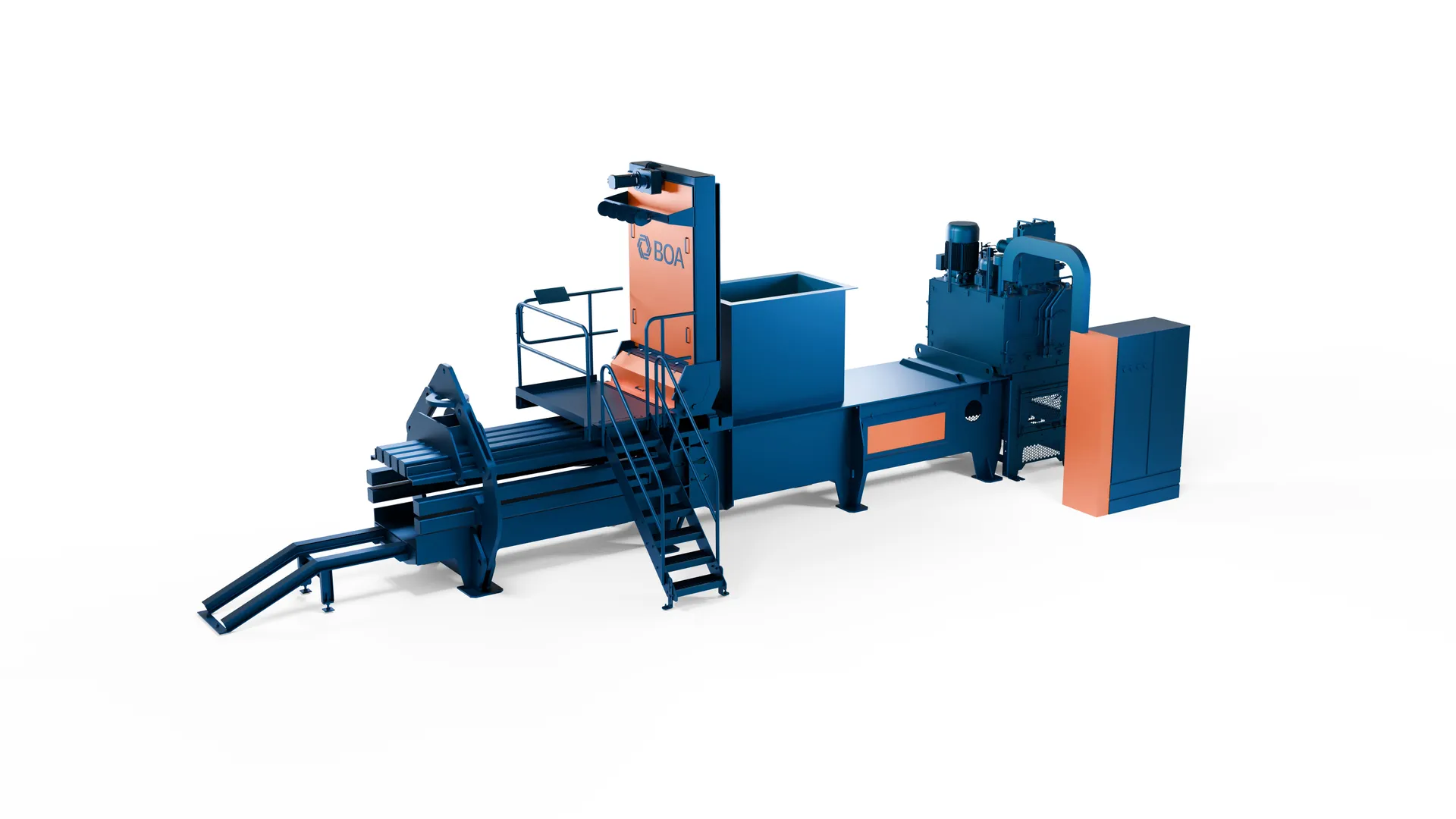

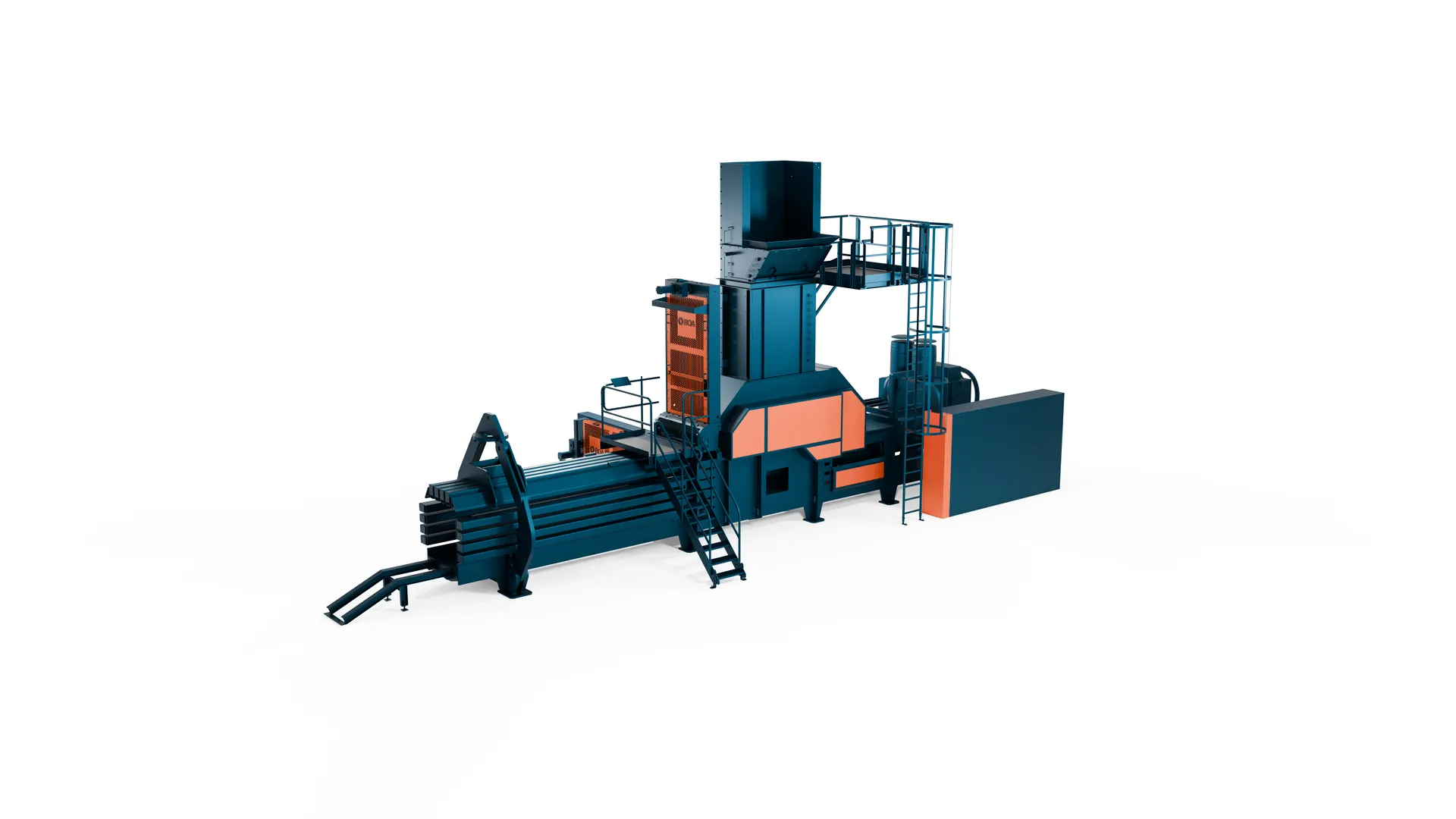

Plastic waste from households or businesses is often light, bulky and difficult to process. Especially with mixed plastic, it is important to work with the right technology. Our M- and D-Series balers are specially designed for this type of material. Thanks to their robust construction, high press force and clever bale channel control, they produce compact, stable bales that are immediately suitable for transport or further processing.

Is the plastic waste delivered in bags? Then our bag opener ensures an efficient and constant material feed. In case of frequent processing of PET bottles, for example, we can integrate our own bottle picker.

To process the waste properly, it is baled by material type. This provides great benefits for storage and logistics, and lowers overall processing costs. The goal is always: heavy, well-stackable bales.

Plastic waste from manufacturing processes

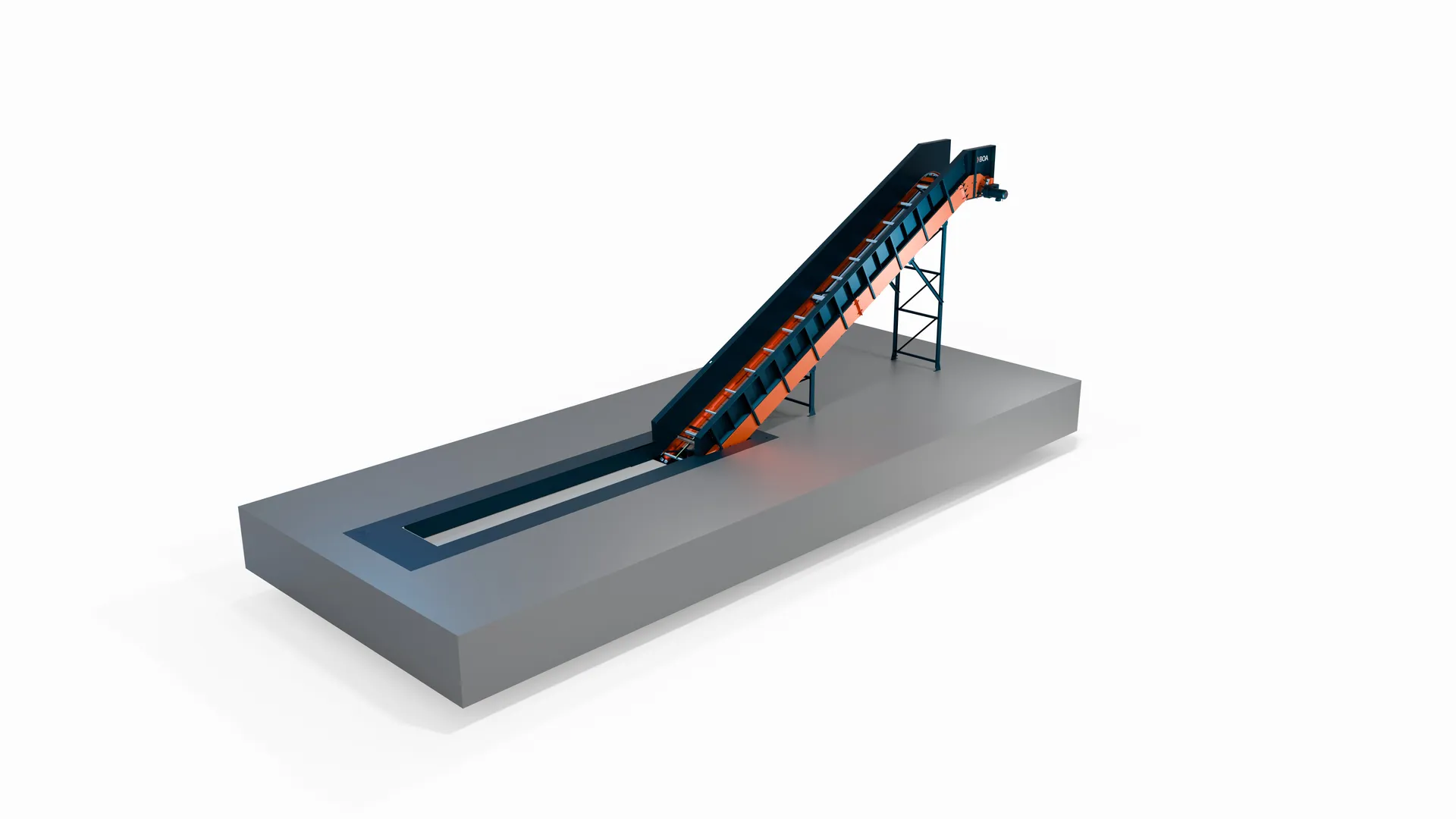

Plastic waste from production processes, such as film residues, cutting losses, rejected injection molded parts or complete rolls, requires a different approach than household plastic waste. BOA offers complete solutions for this with roll cutters and compact horizontal balers such as the Continette or Baseline.

Various types of residual waste, such as HDPE, LDPE or rubber, are often generated during production. This material is excellent for reuse, provided it is properly prepared.

Depending on the type of plastic and its intended use, we recommend a suitable configuration. We cut large plastic rolls into manageable pieces with a reel cutter. These are then processed with a horizontal baler into tight bales, ready for reuse in our own process or for transport to external processors.

Low energy consumption (up to 30%)

Minimal maintenance

Quick and easy operation

Low operating costs with quick ROI

Dense, heavy and well stackable bales

Tiltable binding system

Refu-ram

Double flap system

Remote assistance

Solid construction

BOA provides complete solutions.

Wondering what the right solution is for your process? Contact our experts.